News Center

Latest information, brand activities

Analysis and Correction of Paint Film Defects

Release time:

2021-02-19 16:08

Source:

In the coating process, the paint film will inevitably have problems, especially the use of spraying methods, for the construction skills require high, inexperienced painters are difficult to avoid not producing paint film defects. Some defects occur during the curing and drying of the coating, and some only appear after it is put into use.

Poor construction painting procedures can create a variety of problems. If the construction equipment is not appropriate or the level maintenance is not good, or the construction personnel skills are not good, it is easy to produce coating defects. Experienced construction personnel can avoid some problems, but some problems are inevitable. In addition to the weather conditions have a significant impact on the final result, we need to understand some other conditions that may produce paint film defects, so that we can effectively avoid the problem.

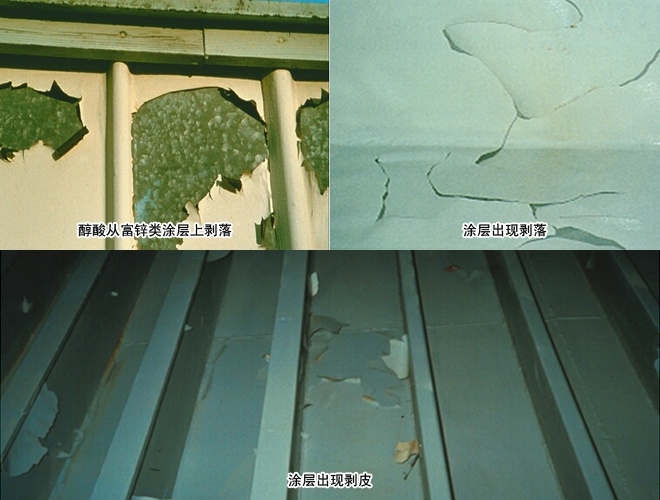

1、剥落/脱落/脱皮(Adhesion Failure/Detachment/Peeling off)

Peeling: Loss of adhesion between a coating and a substrate or another coating.

Possible causes: surface contamination or surface condensation.

Prevention: ensure that the surface is clean, dry and free of any contaminants; the surface is properly treated; according to the correct supporting construction.

Repair: According to the degree of peeling, remove the defect and perform appropriate surface treatment; according to the paint manufacturer's recommendation, use the correct paint system.

2. Dry Spray

Dry spray: because the particles can not flow fully and cannot be leveled, resulting in rough and uneven finish on the surface of the paint film, and its binding force is often poor.

Possible causes: incorrect spraying technology, such as gun distance; quick-drying products (solvent volatilization is too fast); high temperature during construction; too much wind during spraying.

Precautions: Use correct spraying equipment and techniques; use slower drying solvents; spray paint in the right environment; follow recommended construction procedures;

Repair: Before the coating is cured or dry, remove the paint mist with a dry paint brush and remove it with solvent. After the coating is cured or dry, sand and recoat.

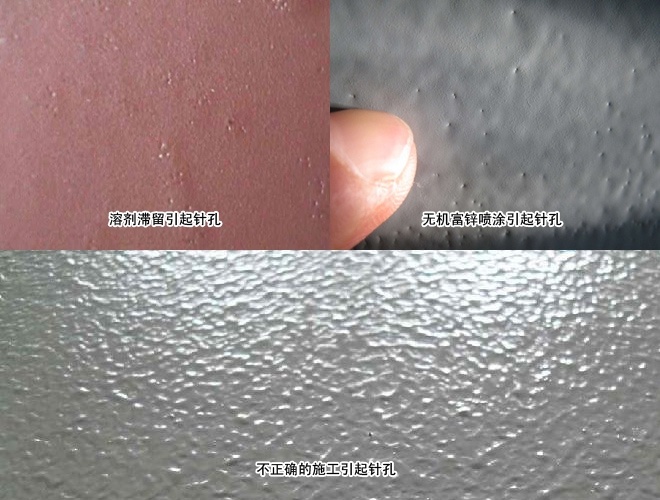

3. Pinhole (Pinholes)

Pinhole: In the process of coating construction and drying, due to the expansion of air or solvent gas mixed in the coating, many craters and small holes are formed in the wet film, and the pores are not combined before the coating is dried.

Possible causes: solvent or air retention in the coating; when coating porous coatings, such as zinc-containing primers, inorganic zinc coatings and metal spraying, pinholes will especially occur; incorrect spraying methods and incorrect use of solvents will also produce pinholes.

Prevention: use the correct construction process, select the appropriate coating system; use the appropriate solvent and construction under good environmental conditions; check the spraying equipment, spray gun and the surface to maintain a reasonable distance.

Repair: Sand, clean and apply suitable sealer/intermediate and topcoat.

4、流挂 (Runs & Sags/curtains)

Sagging: coating construction soon, because the film thickness is too thick, paint in the vertical part of the downward movement or like tears down flow. Sometimes it is shaped like a waterfall.

Possible causes: too thick coating; too much solvent; wrong (lack of) curing agent, or unskilled craftsmanship. Extreme environments (too cold or too hot) are also an obvious cause of sagging.

Prevention: Use the correct coating system, use the correct application process and select the correct dry film thickness

Repair: When the coating is not dry, use a paint brush or roller to remove sagging; when the coating is dry, sand and clean the defective surface as needed, and repaint or repair.

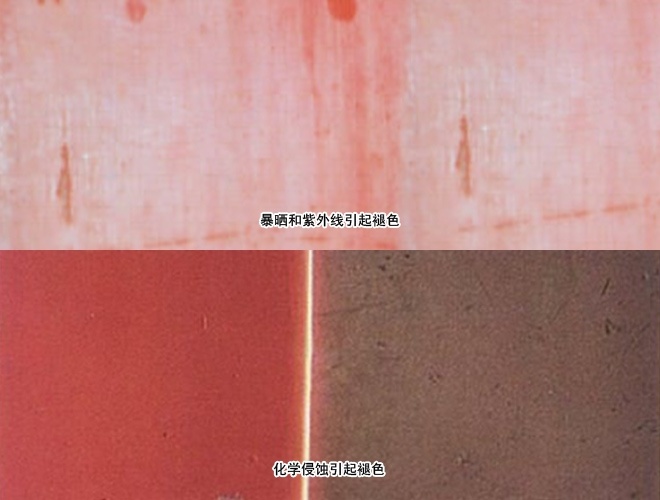

5. Fading (Bleaching)

Fading: The coating partially and/or completely loses its original color.

Possible causes: due to atmospheric exposure or chemical attack; due to atmospheric exposure and ultraviolet rays;

Prevention: Use color-stable pigments/UV-resistant or chemically resistant coatings.

Repair: Remove faded coating, or sand and repaint with a more suitable paint system.

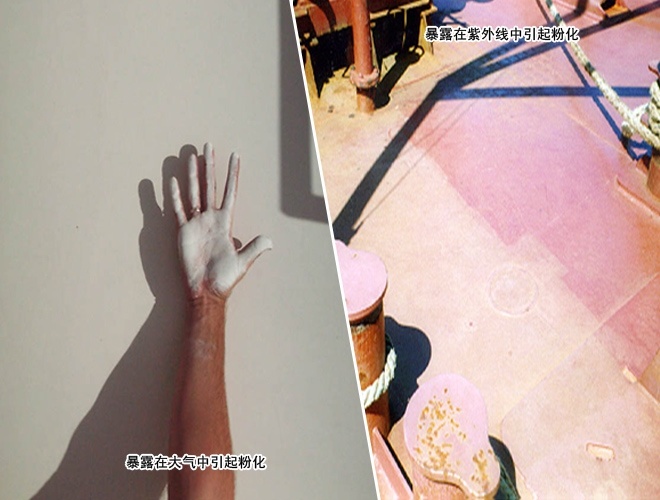

6. Pulverization (Chalking)

Powder: coating surface a layer of fragile powder layer, can also see the coating surface discoloration or fading. The pulverization speed varies depending on the concentration of the pigment and the type of resin selected. Chalking is a characteristic of certain coatings, such as epoxy coatings.

Possible causes: The resin in the paint decomposes when exposed to the atmosphere and/or ultraviolet light.

Prevention: Use a suitable powder-resistant, UV-resistant finish.

Repair: Remove all differentiated deposits and loose materials by sanding or light sand sweeping, and repaint with a powder-resistant topcoat.

7、渗色 (Bleeding-bleed through)

Bleed: The process of diffusion of colored substances from the lower substrate or paint film into and through the upper paint film, resulting in undesirable coloration or discoloration of the paint film.

Possible causes: due to the lower layer of the coating of soluble colored substances after diffusion to the surface of the coating, so that it loses its original color. (especially the bleeding of tar)

Precaution: Decorated areas do not use bitumen/tar-containing primer.

Repair: Sanding and repainting with a more suitable paint system.

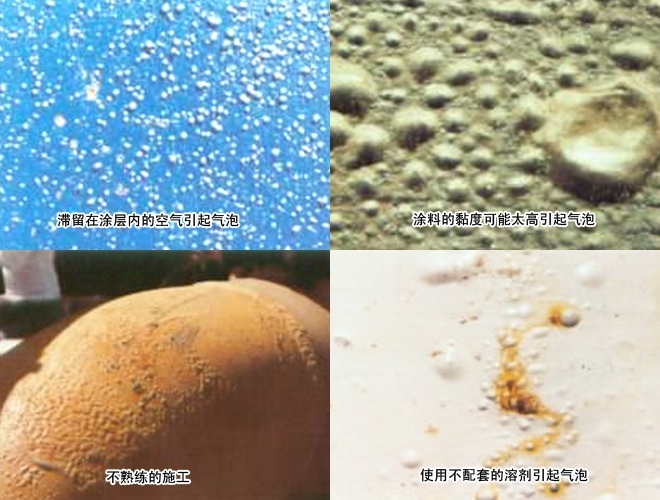

8、起泡(Blistering)

Blistering: On the dry coating surface, dome-shaped protrusions or bubbles caused by the loss of local adhesion between the surface coating and the lower coating surface, which may contain liquid, gas or crystals;

Possible causes: loss of local adhesion due to pollution such as grease, salt, rust, trapped moisture, residual solvent, hydrogen pressure (using cathodic protection), soluble pigments, etc.; Permeable blistering can also occur under water immersion conditions; overcurrent protection can also produce blistering.

Prevention: Ensure proper surface preparation and paint application; use appropriate paint system; use appropriate cathodic protection.

Repair: Depending on the size and type of blisters, remove the blisters or the entire paint system and repair or reapply them.

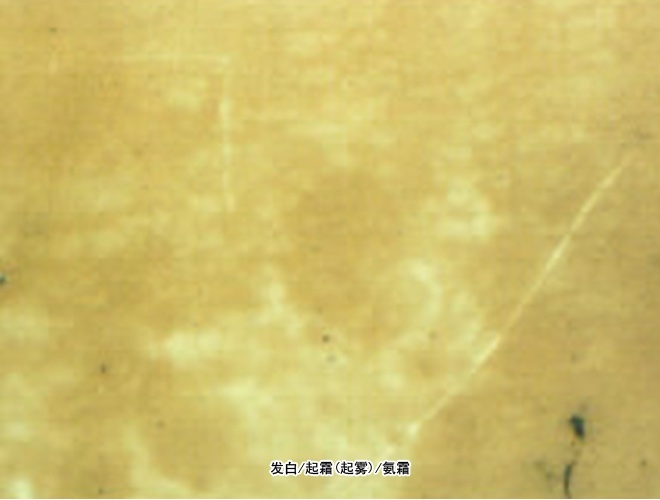

8. Whitening/blooming (fogging)/ammonia cream (Bloom/Blush)

Ammonia cream: A smoky deposit on the surface of the coating, similar to a layer of fruit cream on the surface of grapes, causing the surface of the coating to lose light and shade.

Possible causes: the coating in the curing or drying process, exposed to water condensation and moisture in the environment (ammonia curing epoxy often this phenomenon-amine carbamate); incorrect solvent mixing will also make the coating bloom.

Precaution: Paint is applied and cured under the correct environmental conditions or as recommended by the paint manufacturer.

Repair: Remove the blooming with a clean cloth or a suitable solvent; apply the intermediate/topcoat as recommended by the paint manufacturer.

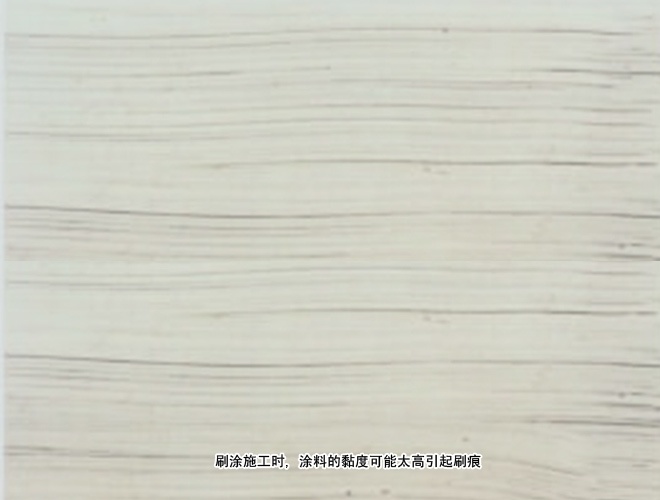

9、刷痕(Brush Marks)

Brush marks: during the brushing construction, the coating is not leveled, and after the coating is dried, the surface is left with unsightly strips of uneven heights and wrinkles.

Possible causes: when brushing construction, the viscosity of the coating may be too high; the use of incorrect solvents; inadequate mixing and unskilled construction; two-component paint, may exceed the use time limit after the paint is mixed.

Prevention: according to the type of paint to choose the method of brushing and reasonable coating thickness; dilute the coating to brush the viscosity; in the use of the specified time limit of construction.

Repair: Depending on the extent of the brush marks, sand the surface thoroughly and repaint with a paint of the right viscosity.

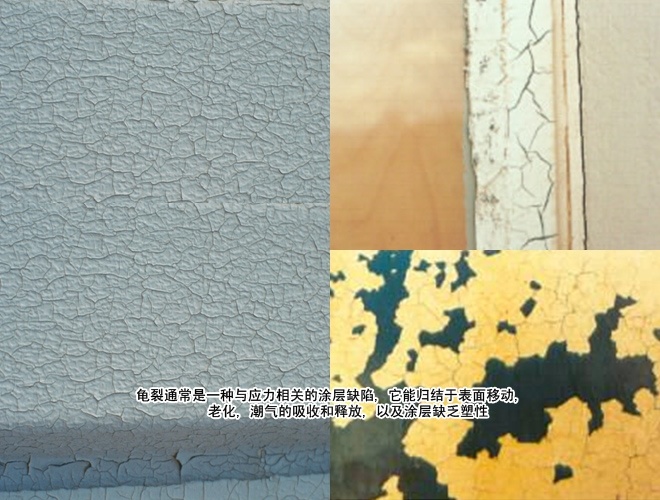

10, fine cracking (Checking)-no bottom

Fine cracking: A small crack that does not penetrate the topcoat of the paint system. Some cracks are quite small and impossible to see without a magnifying glass.

Possible causes: typically coating formulation and/or paint matching problems; the stress of the coating gathers and acts on the surface of the coating, making it brittle and cracking; the plasticity of the coating is poor.

Prevention: Use the correct formulation of the paint system.

Repair: Sand and clean the coated surface first, then apply a suitable intermediate/finish.

11. Crack (Cracking)-exposed bottom

Crack: There are visible cracks on the surface of the coating, which may penetrate into the substrate. Cracking manifests in a variety of forms, from mild to severe.

Possible causes: cracking is usually a stress-related coating defect, which can be attributed to surface movement, aging, moisture absorption and release, and the lack of plasticity of the coating; the thicker the coating, the greater the possibility of cracking.

Prevention: Use the correct coating system, the correct construction process and the correct dry film thickness; use more plastic paint.

Repair: Sand and remove all cracked coatings, reapply the coating system correctly, or use coatings that are more plastic and have less tendency to crack.

12、橘皮(Orange Peel)

Orange peel: The surface of the coating is uneven like orange peel.

Possible causes: poor paint leveling (paint is too thick or the temperature is too low) paint atomization solvent volatilization is too fast spray gun and the surface of the object is too close to the unskilled spray construction, or due to incorrect solvent mixing.

Prevention: use the correct construction technology, choose the appropriate formula of the coating system.

Repair: For places with high decorative requirements, sand, clean and repaint.